The three major application areas of PC engineering plastics are glass assembly industry,automobile industry and electronics and electrical industry,followed by industrial machinery parts,optical discs,packaging,computers and other office equipment,medical and health care,films,leisure and protective equipment.Polycarbonate can be used as door and window glass.Polycarbonate hollow laminates sheet are widely used in protective windows in banks,embassies,detention centers and public places,as well as aircraft cabin covers,lighting equipment,industrial safety baffles and bulletproof glass.

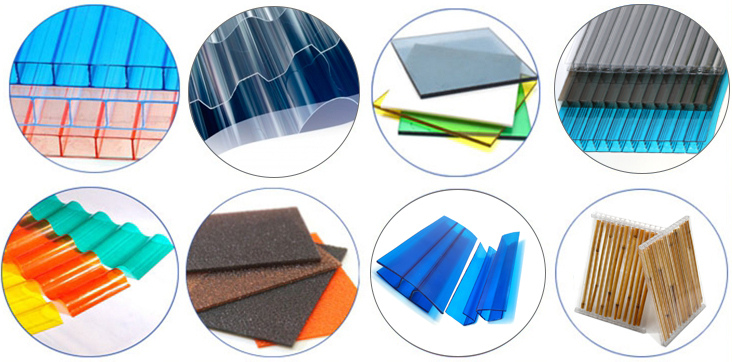

Building Materials Industry

Polycarbonate sheet has good light transmittance,impact resistance,UV resistant and its dimensional stability and good molding and processing performance,making it have obvious technical performance advantages over the traditional inorganic glass used in the construction industry.China has built more than 20 production lines for polycarbonate building materials hollow sheet,and the annual demand for polycarbonate is about 70,000 tons,which will reach 140,000 tons by 2005.

Automotive Manufacturing

Polycarbonate sheet has good impact resistance,thermal distortion resistance,good weather resistance and high hardness,so it is suitable for the production of various parts of cars and light trucks.It is mainly concentrated in lighting systems,instrument panels,heating panels, and Frostware and bumpers made of polycarbonate alloy.

According to data from developed countries,the proportion of polycarbonate used in the electrical and electronic and automobile manufacturing industries is between 40% and 50%. China only uses about 10% in this field.The electrical and electronic and automobile manufacturing industries are the pillars of China’s rapid development. Industry,the demand for polycarbonate in these fields will be huge in the future.The total number of automobiles in China is large and the demand is large. Therefore,the application of polycarbonate in this field has great potential for expansion.

Medical Instruments

Since polycarbonate products can withstand steam,cleaning agents,heating and high-dose radiation sterilization without yellowing and physical performance degradation,they are widely used in artificial kidney hemodialysis equipment and other equipment that needs to be operated under transparent and intuitive conditions.In medical equipment that needs to be repeatedly sterilized.Such as the production of high-pressure syringes,surgical masks,disposable dental appliances,blood separators,etc.

Aerospace

With the rapid development of aviation and aerospace technology, the requirements for various components in aircraft and spacecraft continue to increase, making the application of polycarbonate sheet in this field increasing. According to statistics, there are 2500 polycarbonate components used on a Boeing aircraft alone, and a single plane consumes about 2 tons of polycarbonate. On the spacecraft, hundreds of polycarbonate components with different configurations and reinforced by glass fiber and astronaut protective equipment are used.

Packaging Field

The new growth point in the packaging field is various types of water storage bottles that can be sterilized and used repeatedly. Because polycarbonate products have the advantages of light weight, good impact resistance and transparency, no deformation and transparency when washed with hot water and corrosive solutions, PC bottles have completely replaced glass bottles in some areas. It is predicted that as people pay more and more attention to drinking water quality, the growth rate of polycarbonate consumption in this area will remain above 10%, and it is expected to reach 60,000 tons by 2005.

IT

Because polycarbonate has good and constant electrical insulation in a wide range of temperature and humidity, it is an excellent insulating material. At the same time, its good flame retardancy and dimensional stability make it form a broad application field in the electronic and electrical industry.

Polycarbonate resin is mainly used in the production of various food processing machinery, power tool housings, bodies, brackets, refrigerator freezer drawers and vacuum cleaner parts. And for the important parts of computers, video recorders and color TVs that require high parts accuracy, polycarbonate materials also show extremely high use value.

Optical Lens

Polycarbonate occupies an extremely important position in this field due to its unique characteristics of high light transmittance, high refractive index, high impact resistance, dimensional stability and easy processing and molding. Optical lenses made of optical grade polycarbonate can be used not only for cameras, microscopes, telescopes and optical testing instruments, but also for film projector lenses, copier lenses, infrared auto-focusing projector lenses, laser beam printer lenses, and various Such prisms, polygonal mirrors and many other office equipment and household appliances fields have a very broad application market.

Another important application field of polycarbonate in optical lenses is as a lens material for children’s glasses, sunglasses and safety glasses, and adult glasses. The average annual growth rate of polycarbonate consumption in the world’s optical industry has remained above 20%, showing great market vitality.

CD Manufacturing

With the rise of the information industry, optical discs made of optical grade polycarbonate, as a new generation of audio-visual information storage media, are developing rapidly at an extremely fast speed. With its excellent performance characteristics, polycarbonate has become the main raw material of the world’s optical disc manufacturing industry. The consumption of polycarbonate in the world’s optical disc manufacturing industry has exceeded 20% of the overall consumption of polycarbonate, and its average annual growth rate has exceeded 10%. China’s optical disc production has grown rapidly. According to figures released by the State Press and Publication Administration, in 2002, there were 748 optical disc production lines nationwide, which consumed about 80,000 tons of optical-grade polycarbonate each year, all of which were imported. Therefore, the application prospect of polycarbonate in the field of optical disc manufacturing is extremely broad.

Company Name: Baoding Xinhai Plastic Sheet Co.,ltd

Contact Person: Sale Manager

Email: info@cnxhpcsheet.com

Phone: +8617713273609

Country: China

Website: https://www.xhplasticsheet.com/

Post time: Aug-10-2021